Fatigue and Fracture Analysis and Investigation

Fatigue and fractures widely happened in infrastructure, equipment, facilities in various industries, resulting in huge economic loss and danger to human lives. Fractures include ductile, brittle and fatigue fracture. Fatigue of materials and components occurs when they are under variable and repeated/cyclic loading(s). UTC can help the clients to conduct failure analysis investigation to avoid or minimise the fatigue and fracture incidents or accident by determining the root cause(s) and improving their fatigue/fracture resistance through contract R & D.

Why Choose UTC for Failure Analysis

UTC is one of leading independant investigation company, consists of experts with more than 35 years failure analysis and accident investigation experience and relevant qualifications.

UTC key staff have successfully led and completed thousands of projects in forensic accident investigation and failure analysis for aerospace, marine, petrochemical, electronic and microelectronic, construction, amusement, oil & gas, transportation industries and governmental agencies

UTC's failure analysis and accident investigation services had been well recongnized by industries and government agencies including

Republic of Singapore Air Force,

DSTA, Singapore Civil Defence Force (SCDF),

Ministry of Manpower (MOM), Hyundai (Korea), PUB, SBS Transit, China Taiping Insurance, Rajah & Tann, WongPartnership, Universal Terminal,Takenaka (Japan) and MSIG Insurance, etc.

UTC's failure analysis and accident investigation services are cost-effective, validated by a number of awards on relevant projects from government tenders in GeBiz.

UTC's expert witness and reports on failure analysis and accident investigation were proven and accepted by High Court, State Court, Criminal Court and Arbitration Court.

To contact our experts, please click

EMAIL.

Examples of UTC Recently Awarded Failure Analysis and Accident Investigation Projects:

Investigation on various vehicle fires for MSIG Insurance.

Failure analysis and accident investigation on liquid dispenser fire for Consumer Safety Department of SPRING /Enterprise Singapore.

Failure analysis and investigation on building cladding (aluminium composite panel - ACP) fire at Toh Guan Road.

Failure analysis and accident investigation on explosion of electric storage water heater by Consumer Safety Department of SPRING Singapore/Enterprise Singapore.

Failure analysis investigation on damage items at and/or recovered from fire incident sites (two year contract + one year option) by Singapore Civil Defence Force (SCDF).

Failure analysis on fractured manhole framesets from Public Utilities Board (PUB).

Click

HERE to download the brochure of failure analysis and accident investigation services.

Failure Analysis Services

Forensic Accident Investigation

Fire investigation

Expert witness in litigation

Corrosion engineering

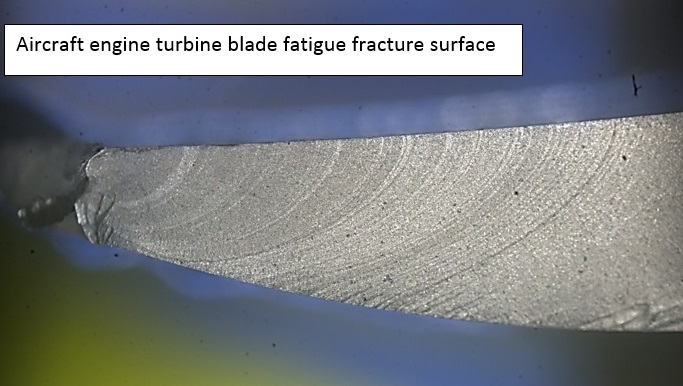

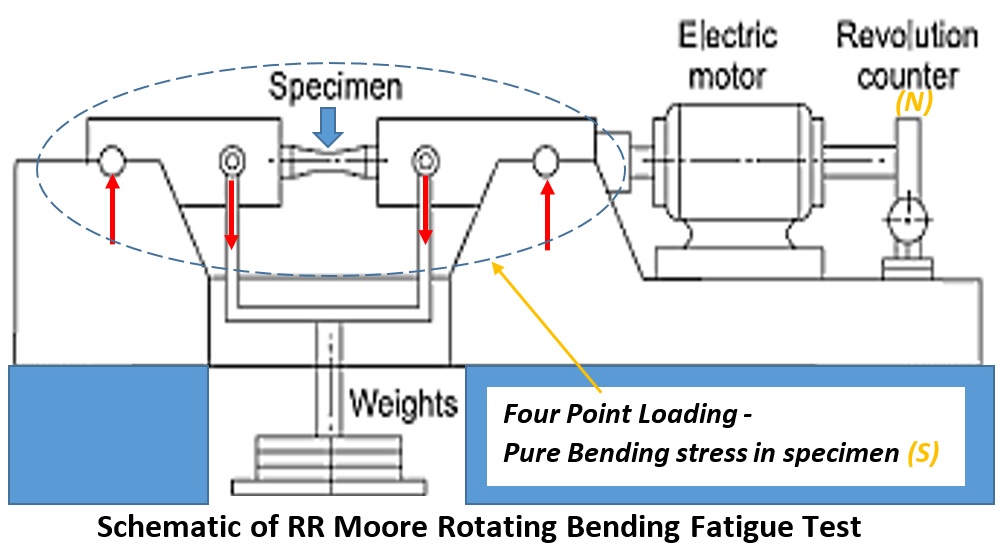

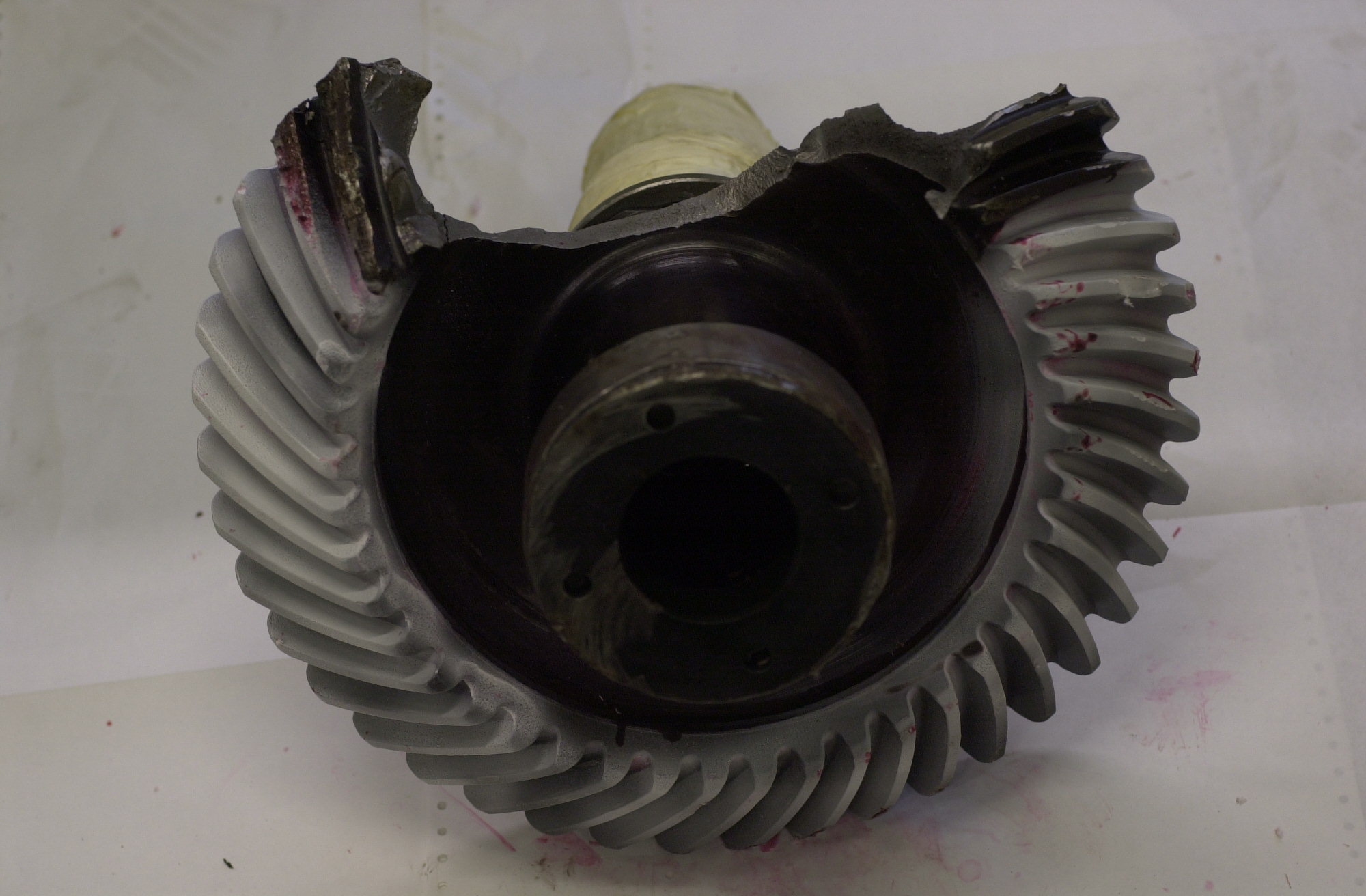

Fatigue and fracture analysis

Traffic accident reconstruction

Design & structural analysis

Condition assessment

Failure Analysis Services

Forensic Accident Investigation

Fire investigation

Expert witness in litigation

Corrosion engineering

Fatigue and fracture analysis

Traffic accident reconstruction

Design & structural analysis

Condition assessment