Failure analysis service (or failure investigation service) is a consulting service which adopts systematic analysis approach and scientific techniques to determine root cause(s) and mechansim(s) of failure(s) and provides counter measures to prevent similar failure or accident recurrence. Failure analysis services are demanded by companies and governments from not only Singapore but also other countries.

Failure analysis experts are sometimes summoned to the Court and act as failure analysis expert witness testifying in the Court to present expert opinions and evidences in case the parties involved in the failure or disputes on the responsibilities ( litigation). For more details of expert witness, please refer to EXPERT WITNESS SERVICES.

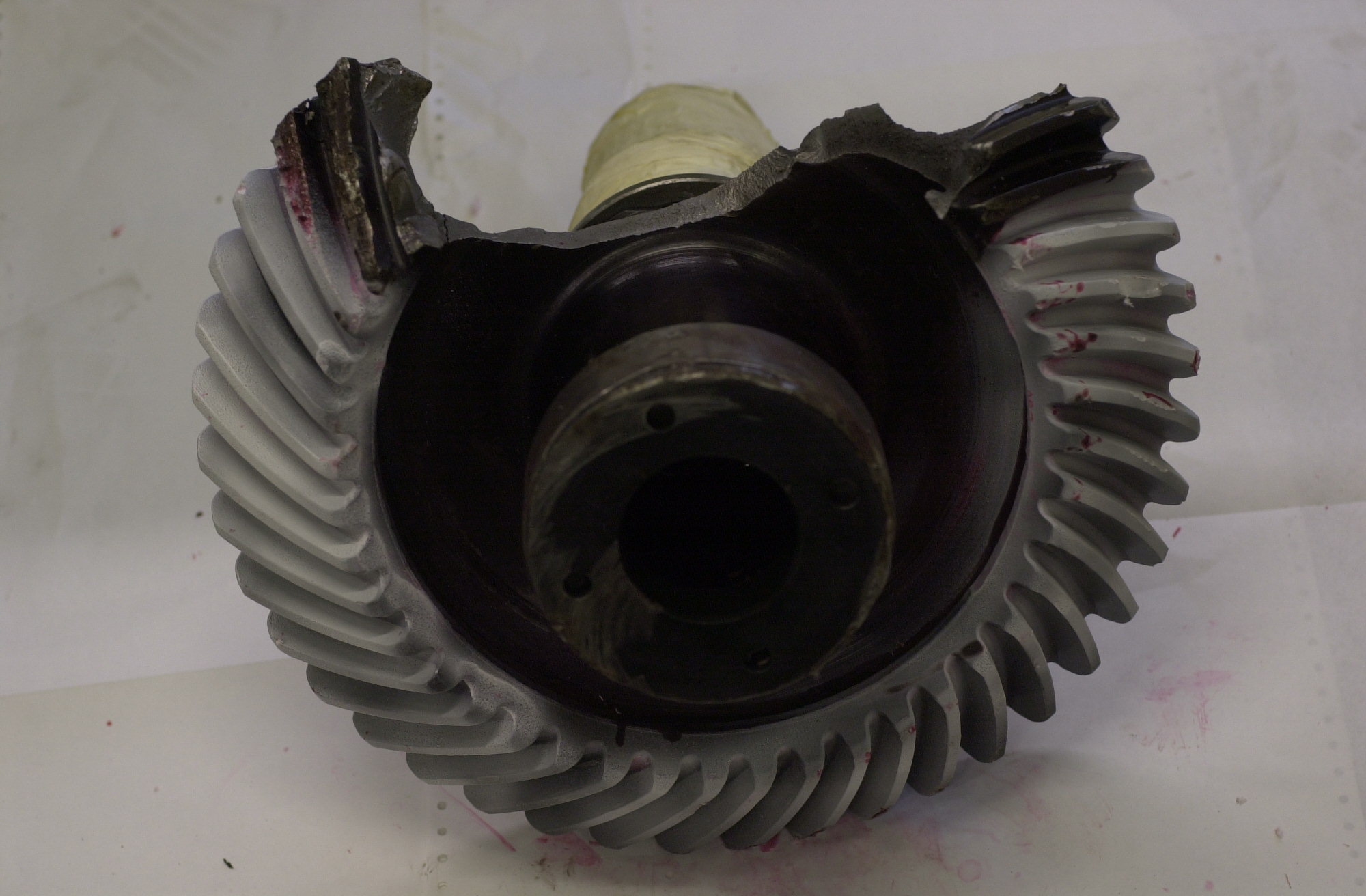

Failure analysis is often called as engineering failure analysis, including mechanical failure analysis or stress failure analysis, component failure analysis, electrical failure analysis and material failure analysis. In case of damages involved in equipments or facilities, failure analysis can be called damage analysis (or damage investigation). Inspection is often involved in failure analysis or related investigation.

UTC failure analysis expert Dr George YU featured in Singapore MediaCorp TV programs

UTC failure analysis experts recently published technical papers related to industrial failure analysis in international journals:

To contact UTC failure analysis expert, please click EMAIL: enquiry@ut.sg or Call (65)81380509.

UTC failure analysis experts with extensive relevant experience were engaged by Singapore government agencies (MOM, SCDF, ESG, PUB), MNCs and insurance companies for conducting a number of high profile failure analysis, accident and fire investigation cases, lecturing "Failure Investigation Analysis" course for Republic of Singapore Air Force (RSAF) & "Vehicle Fire Investigation" for LTA Singapore, and testifying in different Courts as failure analysis expert witness and accident expert witness. UTC expert had been featured in Singapore Newspaper "Straits Times" and MediaCorp TV programs for failure analysis and accident investigation.

Failure analysis services

Forensic accident investigation

Traffic accident reconstruction

Fire investigation services

Expert witness in litigation

Corrosion engineering

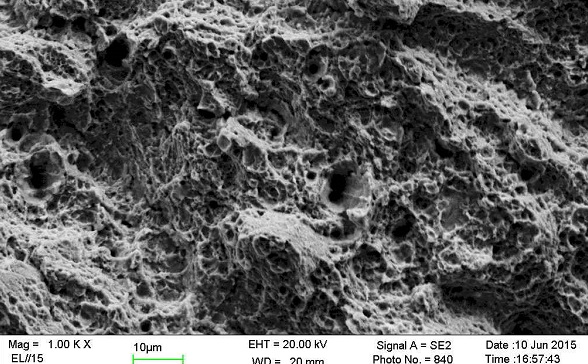

Fatigue and fracture analysis

Design & structural analysis

Condition assessment

Failure analysis services

Forensic accident investigation

Traffic accident reconstruction

Fire investigation services

Expert witness in litigation

Corrosion engineering

Fatigue and fracture analysis

Design & structural analysis

Condition assessment